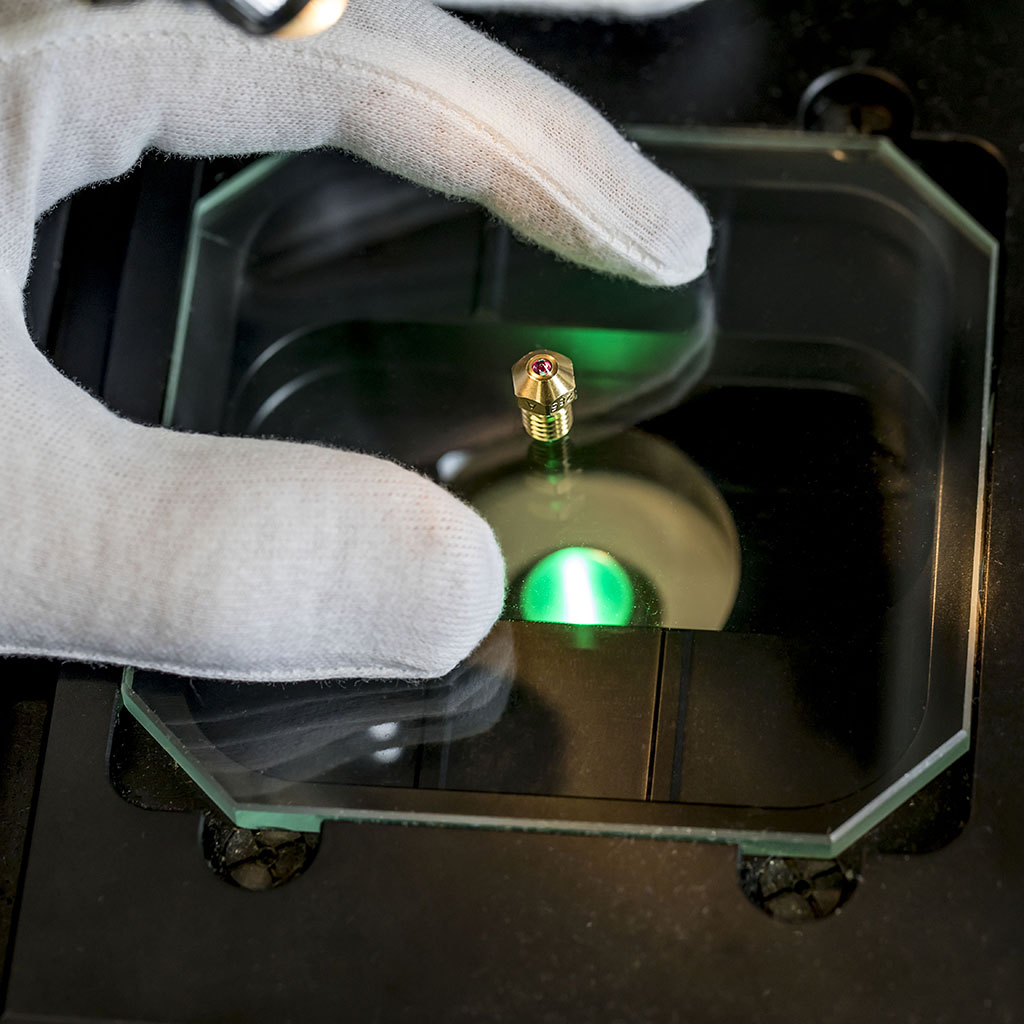

One nozzle

The Olsson Ruby will work with a huge range of materials. PLA, ABS, CPE/PET, Nylon, and composites with abrasive additives such as Carbon fibre, Steel, Wood, Boron Carbide, Tungsten and Phosphorescent pigment, are some of the materials sucessfully tested so far.

Highly wear resistant

The ruby mounted at the tip makes sure that even the toughest materials will be printable. It was originally designed for printing with Boron Carbide (B4C), the third hardest known material in the world.

Excellent heat conductivity

Since most of the Olsson Ruby is made from brass, with its excellent heat conductivity, performance and throughput is first-class.

Verified performance

People all over the world have been testing different iterations of the ruby nozzle since early 2016. We are very happy to have received only good printing results from this community.

Speed

By using the 0.6, 0.8mm and High Output versions it is possible to reach a higher throughput and speed than ever before for abrasive materials, while retaining wear-resistance and reliability.

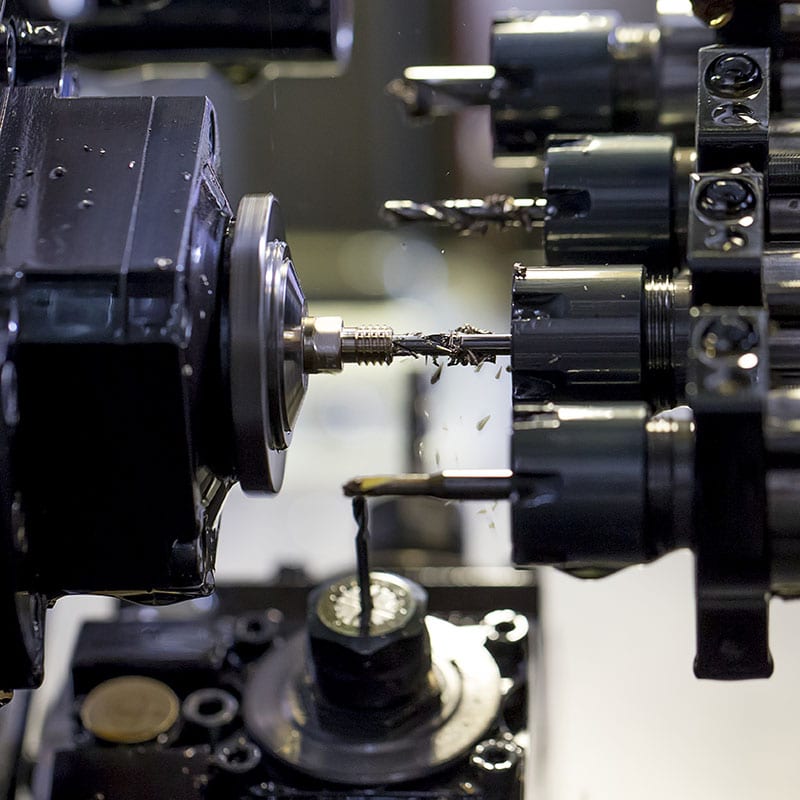

SUPERIOR RAW MATERIALS

PRECISION MANUFACTURING